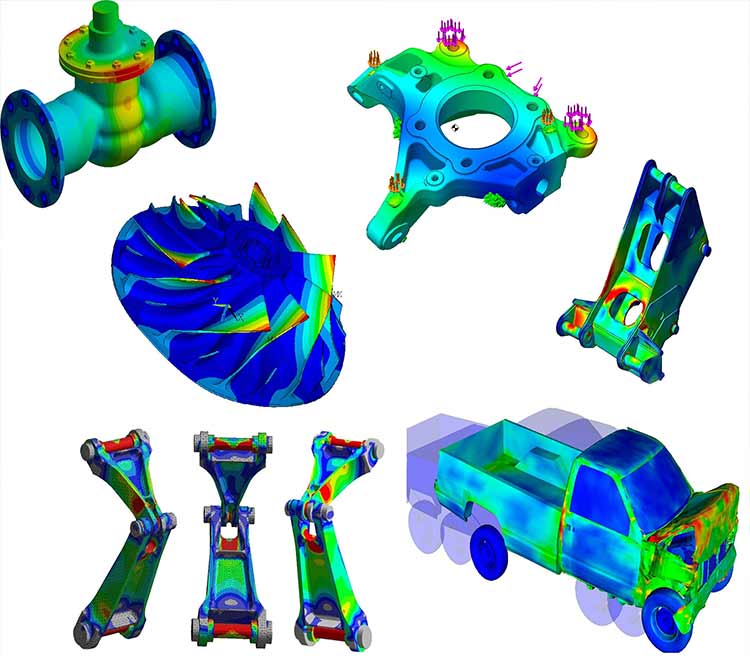

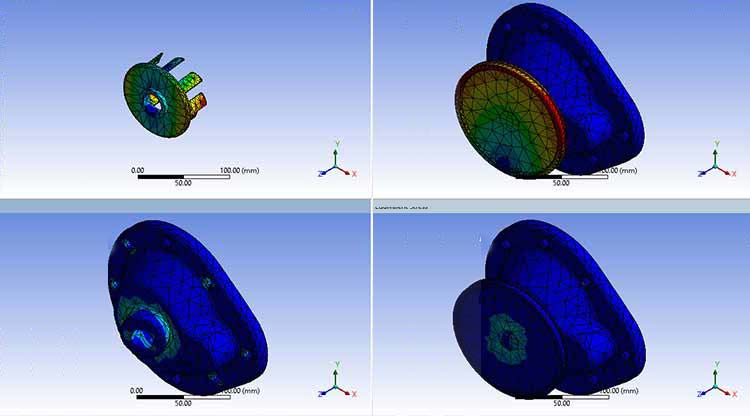

Finite Element Analysis

Your design appears wonderful, but can it withstand the variable strength and stability circumstances in real life? Are you confident that the design you've envisioned will resist structural and performance failure? Finite element analysis is a fundamental technique for verifying, validating, and optimizing the performance of any product throughout its life cycle.

Dreamzeal Technologies Pvt. Ltd. is a prominent FEA service provider for a variety of industries, including automotive, manufacturing, healthcare, aviation, and more. Our FEA services aid in shortening design to market time, avoiding unexpected field failure, lowering physical test costs, and determining the best design from many concepts, among other things. We give timely technical support to tackle any complex challenges in terms of static, dynamic, structural, and thermal issues.

Our mechanical engineers, quality analyzers, and FEA specialists work as an extension of your in-house team, bringing the most up-to-date technical knowledge and technologies to assure faultless designs. Aerospace components, process equipment and more all benefit from our FEA services. We provide a comprehensive range of FEA services in India, including everything from modelling to final manufacture of your unique design concepts. The following are some of our most important finite element analysis solutions.